Production

System

Production System

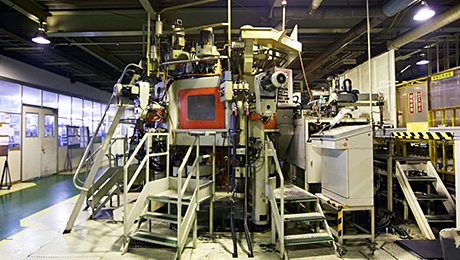

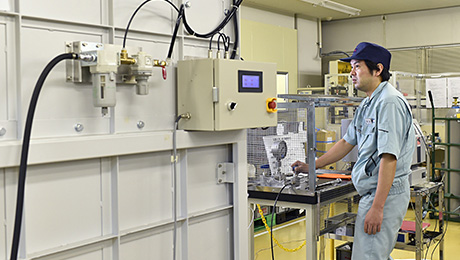

We have our own production plant with the latest facilities. From high-mix, small-lot production to mass production, we can meet various needs.

At Hamai, we have the Fuchu Plant (in Tokyo Prefecture) as the production plant for high-pressure valves and the Otaki Plant (in Chiba Prefecture) as the production plant for LP gas valves and ball valves. We have clean rooms and ultra high-pressure boosters of 150 MPa and have built automated production lines for mass production and cellular production lines for high-mix, low-volume production. We can thus meet various supply needs.

We have a production base outside of Japan, and it is shipping high-quality products to the global market

In 2013, Hamai established the local corporation Hamai Korea in South Korea. Its main products are valves for semiconductors and high-pressure valves. It ships products to South Korea, China, and other countries of Asia?products that comply with the industrial standards of each country?and contributes to the development of industry.

Production

Production

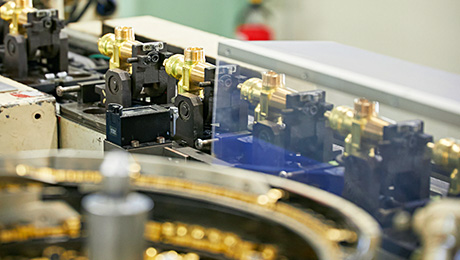

We possess mass-production facilities

We possess mass-production facilities for LP gas valves where we can produce over 5 million units annually in response to mass demand.

We have built a mass-production system

We make use of our original mass-production system in a flexible way, and we have automated manufacturing with unmanned lines and robots from manufacturing to testing and shipping.

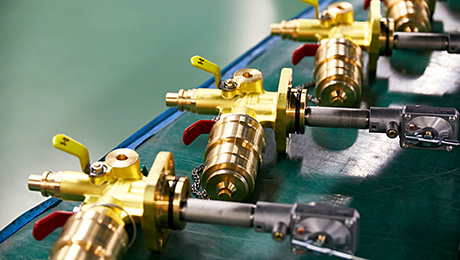

We can handle high-mix, low-volume production

With cellular production, we can accommodate low-volume, high-mix production in response to each customer’s needs.

We can comply with the standards of many countries

We can manufacture products that comply with the legal and industrial standards of countries and regions worldwide, including Europe, the USA, China, and South Korea.

Production Technology

Production Technology

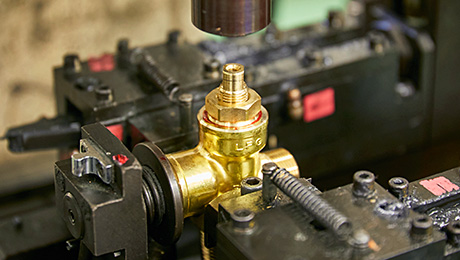

We manufacture cutting-edge hydrogen valves

We manufacture cutting-edge valves: hydrogen valves for FCVs, valves for hydrogen stations, valves for hydrogen trailer cylinders, and more.

Our 150 MPa test instrument is among the largest in Japan

We have a 150 MPa test instrument, which is among the largest in Japan. We can develop high-performance valves for an extensive range of pressures.

Our clean room is of a high class

We have a clean room dedicated to manufacturing valves for semiconductor material gases. This minimizes the particles that enter during assembly.

Various state-of-the-art 5-axis processing machines

We are equipped with various large state-of-the-art 5-axis processing machines for process completion from materials to product on one machine.

R&D Laboratory

R&D Laboratory

Our constant-temperature chamber is high-performance

We perform evaluation tests and accelerated evaluation tests anticipating use in a wide range of temperatures.

Our coordinate-measuring machine is state of the art

We have introduced the latest laser coordinate-measuring machine and are raising the precision of our products by measuring precisely.

We design using 3D CAD

We design using 3D CAD, which lets us visualize the finished form. This allows us to be highly precise in designing our products.

We prototype with a 3D printer

With our high-precision 3D printer, we can make prototypes with speed.

We have our own dedicated lab for performing numerous tests in our research and development: flow rate test, pressure cycling test, temperature cycling test, vibration test, high and low temperature operating tests, thermal shock test, and the like.

PRODUCTION